WOODWORKING TECHNOLOGY: BACK TO NORMAL?

- 2023-05-13

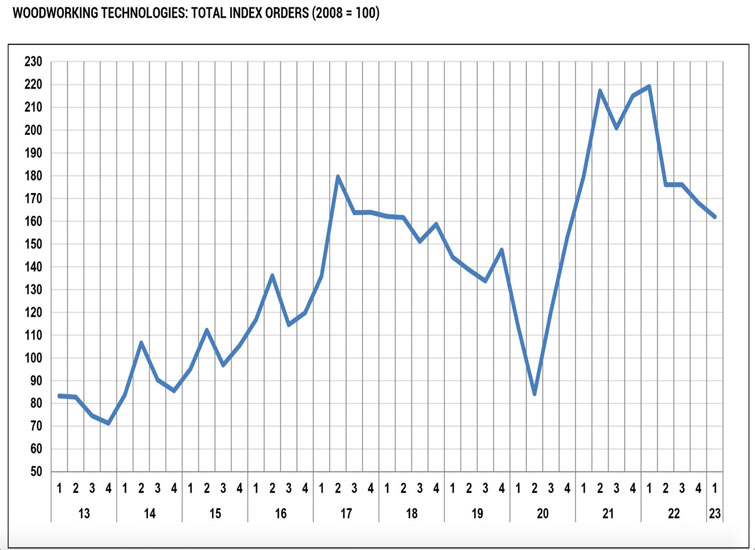

The first quarter 2023 confirmed a slowdown of orders for Italian woodworking and furniture technology. The quarterly survey by the Studies Office of Acimall (the association of Italian woodworking technology manufacturers) shows a negative trend for the fourth quarter in a row. This information must be evaluated accurately, especially considering the exceptional growth that characterized the second part of 2020 and the whole year 2021, recording a trend that has been unprecedented in the past decades. The slowdown that started in the second quarter of 2021 can be considered “physiological”, but the negative trend in the January-March 2023 period causes some worries. In the first quarter of this year, orders recorded a 25.7 percent reduction compared to the same period of the previous year, due to decreasing demand from international markets (down by 20.6 percent) and the significant shrinkage of the domestic market (minus 38.9 percent). It should also be noticed that the period of comparison, January-March 2022, was still an expansion phase, with significant growth rates in Italy and abroad, supported by public subsidies in many countries that, on one hand, really helped many industries overcome the consequences of the global sanitary emergency, but on the other, altered the normal evolution of the market. The reduction of orders is reflected onto the months of ensured production, dropping from an average of 6.1 months in October-December 2022 to 5.2 months in January-March 2023. The inflation trend – which in 2022 was in line with the economy in general – seems to be braking in the first months of 2023: the increase of sales prices for Italian wood and furniture technology was limited to 0.6 percent. Source:ACIMALL The opinions collected by the quality survey for the quarter under scrutiny reveal that the interviewed companies expect substantial stability of production (71 percent), while 24 percent indicates a growing trend and 5 percent a decrease. Employment is increasing according to 14 percent of the sample, stationary for 81 percent, decreasing for 5 percent. Available stocks are stable for 62 percent of the interviewees, while the remaining 38 percent is equally divided between those who indicate an increase (19 percent) and a reduction (19 percent). The forecast survey gives an overview of the scenarios that might emerge in the short term: 38 percent of the sample expect a substantial stability of orders from the foreign markets; such orders will decrease according to 38 percent and further increase according to 24 percent. Looking at the Italian market, 57 percent of the interviewees predict substantial stability, 19 percent increasing orders and 24 percent decreasing orders. Source:ACIMALL

2023 Taiwan Woodworking Machinery Competition Winners

- 2023-04-22

Woodworking Machinery

The Outstanding Design Award:

Anderson smart production system for panel furniture (Anderson Industrial Corp)

Anderson smart production system for panel furniture

Anderson utilized the 50 years experience in woodworking machinery industry, integrates mechanical, electrical and software three key features of automation, developed a full production system for panel furniture. Provides better, smarter, efficient and eco-friendly production system for the market, to bring the production to next level.

Description of 7 Key Design Features:

(1)Practicality: Optimize the CNC cutting and drilling capability, with automation integrated, provide stable and high efficient production.

(2)Innovative: Our parametric cabinet software and production nesting software, much reduce the production preparation time, and much organized the production procedures.

(3)Accuracy: With our parametric cabinet software and production nesting software, all working programs are controlled by production office, operator only need to scan barcode to operate machine, much reduce operational error. Also with Anderson CNC production line, we never compromise on precision and production quality, and proudly to provide the best machine in the market to customers.

(4)Smart integration: Integrate vision system at unloading system to provide accurate parts pick up

and distributing to next process, make whole automatic system smoother.

(5)Market penetration: After years research in the market, Anderson provides integrations on tradition and digitalization production for customers, this helps customer easier to implement smart production concept, which changed the trend of panel furniture production.

(6)Eco-friendly: Use Anderson offcut management system can easily increase the utilization of material and reduce waste as much as we can. Much reduce waste without interrupt the automatic production line.

(7)Safety: Each automatic processes with safety fence and barrier to make sure the safety of operator.

.jpg)

.jpg) The Outstanding Product Award:

Just in time packing solution-smart boxing machine (Innovator Machinery Co., Ltd)

The Outstanding Product Award:

Just in time packing solution-smart boxing machine (Innovator Machinery Co., Ltd)

.jpg) The distinguished Product Award:

Optimization multi rip saw(Kuang Yung Machinery Co Ltd.)

The distinguished Product Award:

Optimization multi rip saw(Kuang Yung Machinery Co Ltd.)

.jpg) The Distinguished Design Award:

Intelligent 4 side moulder (Leadermac Machinery Co., Ltd)

The Distinguished Design Award:

Intelligent 4 side moulder (Leadermac Machinery Co., Ltd)

.jpg) The Distinguished Product Award:

Quick change 1mm and 2mm edge banding machine(Oav Equipment and Tools, Inc)

The Distinguished Product Award:

Quick change 1mm and 2mm edge banding machine(Oav Equipment and Tools, Inc)

.jpg) Peripherals

The Distinguished Product Award:

3 in 1 dc brushless motor (Co-matic Machinery Co., Ltd.)

Peripherals

The Distinguished Product Award:

3 in 1 dc brushless motor (Co-matic Machinery Co., Ltd.)

.jpg) Dust evacuate (Lu Yen Pcd Cutters Co., Ltd)

Dust evacuate (Lu Yen Pcd Cutters Co., Ltd)

.jpg) The Distinguished Design Award:

Automatic profile cutter grinner-cnc (Leadermac Machinery Co., Ltd)

The Distinguished Design Award:

Automatic profile cutter grinner-cnc (Leadermac Machinery Co., Ltd)

.jpg)

Current Status of Global Woodworking Machinery Industry

- 2023-02-25

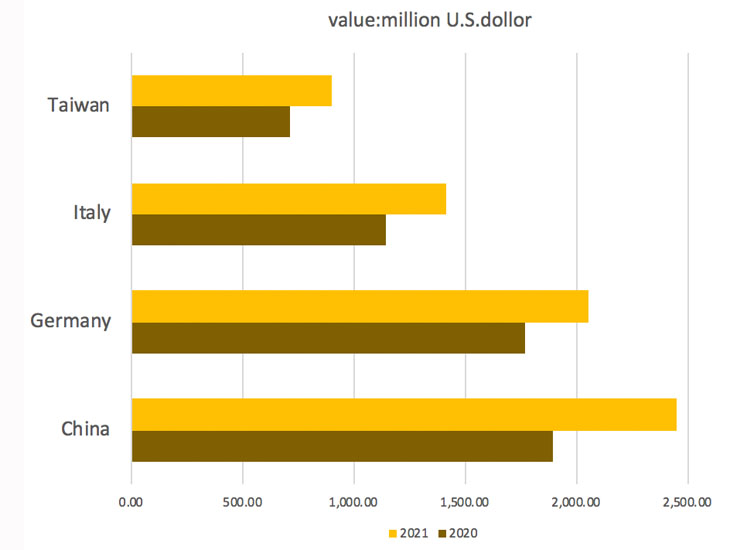

According to ITC (International Trade Centre) data ( Figure 1 and Figure 2), the global woodworking machinery export value in 2021 is about 9.74 billion US dollars, ranking first with mainland China, accounting for 25.3% of the global woodworking machinery export value (2.46 billion U.S. dollars), followed by Germany 21% (2.05 billion U.S. dollars) and Italy 14.5% (1.41 billion U.S. dollars). Taiwan's woodworking machinery exports rank fourth in the world, with an export value of about 900 million U.S. dollars, accounting for the world's The export ratio is 9.3%, and its strength should not be underestimated. The industry is also actively breaking through the development bottleneck, moving forward with "digitalization and intelligence" as the development direction, and striving to expand brand awareness in the international market.

"Smart Manufacturing from Anderson"

- 2023-01-05

In recent years, with the process of Industry 4.0 innovation, electrical component suppliers and software system suppliers of various integrated solutions have also followed the development trend. In addition to the covid-19 epidemic storm since 2020, the ever-changing market trends have catalyzed the transformation and upgrading of many industries. Smart manufacturing is one of the most comprehensive topics. How should smart manufacturing be done?

The perspective of Anderson, each industry has its production process and the supply/demand of upstream/downstream ecological chains are different, and it cannot be consistent for all. It is necessary to consider the possibility of phase in and reserve the possibility of future expansion and upgrading.

For the integration of smart manufacturing, the factory obtains the big data of the production process through the sensor on the machinery equipment, and makes a self-judgment with the front-end and back-end information processing software platforms to issue decision-making instructions, and sends them back through the system to processing equipment and automatic execution of programs, etc., the advanced processes and models of this type of function belong to a part of smart manufacturing.

.jpg) In other words, smart manufacturing is the various links in the production process of "smart machinery" can be integrated with related applications as long as IoT, cloud computing, big data, and AI artificial intelligence, and through network data streams, all devices can communicate with each other. The ultimate goal is to exchange information with each other in real time, and replace the traditional manufacturing process in real-time and quantified transparent management.

In the field of woodworking machinery, it is our direction to support “system furniture manufacturers” to introduce intelligent production. The first stage is to assist the industry to have "machinery and or so equipment to be more intelligence". In addition to the need to add more sensor components to the mechanical equipment itself, it is also necessary to optimize the human-machine interface of the machine operation so that it is not only to operate friendly, but more importantly, it can predict the data obtained from the sensor and temporarily store it locally. Directly compatible with external data processing software platform for real-time information exchange. After the industry possesses the basic elements of intelligent machinery, Anderson further thinks for customers and proposes a variety of automated upgrades before and after manufacturing integration solutions, including automated equipment such as robotic arms or Anderson self-developed crane type pick and place modules, etc., through integration the key to the combination of solutions is to optimize and improve the traditional manufacturing process during the hardware upgrade process, simplify the labor intensive level, and reduce the defect-rate caused by human errors in the original manufacturing process. In addition, through the network and the software data processing platform can also transmit the factory's manufacturing big data to mobile devices in real time, allowing management to grasp the production status more quickly.

In other words, smart manufacturing is the various links in the production process of "smart machinery" can be integrated with related applications as long as IoT, cloud computing, big data, and AI artificial intelligence, and through network data streams, all devices can communicate with each other. The ultimate goal is to exchange information with each other in real time, and replace the traditional manufacturing process in real-time and quantified transparent management.

In the field of woodworking machinery, it is our direction to support “system furniture manufacturers” to introduce intelligent production. The first stage is to assist the industry to have "machinery and or so equipment to be more intelligence". In addition to the need to add more sensor components to the mechanical equipment itself, it is also necessary to optimize the human-machine interface of the machine operation so that it is not only to operate friendly, but more importantly, it can predict the data obtained from the sensor and temporarily store it locally. Directly compatible with external data processing software platform for real-time information exchange. After the industry possesses the basic elements of intelligent machinery, Anderson further thinks for customers and proposes a variety of automated upgrades before and after manufacturing integration solutions, including automated equipment such as robotic arms or Anderson self-developed crane type pick and place modules, etc., through integration the key to the combination of solutions is to optimize and improve the traditional manufacturing process during the hardware upgrade process, simplify the labor intensive level, and reduce the defect-rate caused by human errors in the original manufacturing process. In addition, through the network and the software data processing platform can also transmit the factory's manufacturing big data to mobile devices in real time, allowing management to grasp the production status more quickly.

.jpg) In the process of moving towards the goal of evolution and upgrading of smart manufacturing, Anderson keeps improving and continues to look for collaborating manufacturers to jointly create diversified development possibilities in order to meet different customer needs. Therefore, Anderson has developed into not only a manufacturer of mechanical equipment, but also a developer and maintainer of software, and an integrator capable of cross-system integration technology.

Facing all new challenges, Anderson insists on innovation and continuous research and development, and diagnoses the most suitable solution for customers, so as to jointly achieve the vision expected by customers and Anderson.

In the process of moving towards the goal of evolution and upgrading of smart manufacturing, Anderson keeps improving and continues to look for collaborating manufacturers to jointly create diversified development possibilities in order to meet different customer needs. Therefore, Anderson has developed into not only a manufacturer of mechanical equipment, but also a developer and maintainer of software, and an integrator capable of cross-system integration technology.

Facing all new challenges, Anderson insists on innovation and continuous research and development, and diagnoses the most suitable solution for customers, so as to jointly achieve the vision expected by customers and Anderson.

WEINIG launches largest group-wide invest-ment program in the company's 117-year his-tory

- 2022-12-02

The WEINIG Group announced the launch of a comprehensive, large-scale investment project of more than 120 million euros on June 2, 2022. The Tauberbischofsheim site alone, the headquarters of the company with its 117-year track record of success, accounts for around 70 million euros of the total investment. The supervisory board of the WEINIG Group has approved a comprehensive, Group-wide investment program that will fundamentally reposition the Group and its headquarters in Tauberbischofsheim. In total, more than 120 million euros will be invested over the next 5 years. For the Voitsberg site in Austria, the production location of the subsidiary HOLZ-HER, 15 million euros have already been approved in advance and will be invested in assembly, production and logistics. The newly adopted program focuses mainly on the solid wood division of the mechanical engineering company. With 117 years of history at its main site in Tauberbischofsheim, the long-established company has set up a completely new site concept that will sustainably modernize production, significantly optimize delivery capability for customers and improve the working environment for its employees. This will included a new logistics center, a new manufacturing concept and new production facilities, as well as new exhibition and customer training rooms. Around 70 million euros will be invested in the infrastructure of the Tauberbischofsheim site alone. The supervisory board and the management board emphasized how the upcoming investments will position the company for the future. Dr. Thomas Bach, Chairman of the Supervisory Board of WEINIG AG, pointed out that it is part of the WEINIG DNA to see crises as opportunities, and that not least the Corona pandemic has provided room for conceptual work: “We looked for, identified and seized an opportunity in the crisis. As a result, we can confidently say today: WEINIG is fit for a successful future.” Chief Executive Officer Gregor Baumbusch explained that the wood processing industry is a growth sector that is getting an additional boost through sustainability and climate protection. The demand for machines and solutions that serve this market is correspondingly high and continues to rise. A further 40 million euros will therefore be invested in expanding the product portfolio. Mr. Baumbusch stated: “Today, we already have the broadest product portfolio of any supplier in the solid wood industry worldwide. Especially in the rapidly growing segment of timber construction, we will be able to offer our customers even better solutions from a single source, namely WEINIG, in the future.” Chief Technology Officer Dr. Georg Hanrath added that the future belongs to the triad of sustainable production, sustainable machines and the sustainable products manufactured on them. WEINIG is doing its part. Dr. Thomas Bach and Gregor Baumbusch expressed their thanks to the supervisory board and the shareholders, and in particular the works council and the employees of the WEINIG Group. He added that it is up to each and every one of us to ensure long-term economic success. The workforce is fully behind the planned measures and is looking forward to the improvements they will bring. Works council chairman Rainer Haag commented: “It is a joint project. Only if we all work together can we succeed. We have been discussing what that looks like over the past few months. The most important thing is that no jobs are cut. On the contrary, we will grow!” The machine builders from Tauberbischofsheim are prepared to tackle the future. Source from : WEINIG Group

OAV has won the "Rising Star Award"!

- 2022-11-28

On November 16, 2022 (Wednesday), Oav attended the "Rising Star Award" ceremony, and received the award. The Ministry of Economic Affairs supports Taiwan's Small and Medium Enterprises with actions, in total of 64 outstanding companies won awards, and 16 of them won the Rising Star Award. The Rising Star Award celebrates local businesses that go above and beyond in their business. High competitiveness, corporate management, and sustainable ESG development are the main criteria. Research and Development by Made in Taiwan, the enterprises provide customers with high-quality, high value-added products. OAV specializes in the production of woodworking machinery. Use OAV for brand awareness. Stick to 100% MIT. With a consistent mission to combine service and quality, it has grown from its humble beginnings to provide impeccable woodworking machinery for 120 agents around the world while continuing to provide the best value for their customers.