Pietro Gheller is the new Director of SCM Wood Division

- 2024-04-26

Pietro Gheller, formerly Product&Markets Director of SCM Wood Division, takes over the running of the same Division and the position previously held by Luigi De Vito who continues as General Manager of Scm Group. Pietro Gheller was born in Vicenza 48 years ago and, in 1997, took part in the International Business Program at Stockholm School of Economics and in 1999 graduated from the Bocconi University in Milan in Business Economics. Since 2000, over the course of his long professional career, he has held strategic consulting positions and ones of managerial responsibility in sales, commercial marketing and the supply chain, working for important commercial organisations and multinationals in Italy and abroad in the Fast-Moving Consumer Goods, Durable Goods and Industrial Machinery sectors. In 2019, he joined Scm Group as Sales&Markets Director in the Wood Division, taking charge of and handling the strategic management of more than twenty of the group’s branches and the entire operating sales network in Italy and abroad. Under his commercial guidance, SCM increased its direct presence on key markets with new branches opening in Turkey, India, Southeast Asia and the Balkans, as well as establishing strategic commercial partnerships like the one with the Swedish company Randek AB in the systems for timber construction sector. In 2022, he was appointed SCM’s Product&Markets Director, taking charge of the Business Units and, therefore, of the different technologies which make up the group’s vast range of products dedicated to the entire secondary wood processing industry. Since 11 April 2024, he has been Director of the Wood Division, taking charge of SCM’s Industrial and Customer Care departments together with the technology and commercial development departments. “I’d like to thank Scm Group’s Board of Directors and General Management for the trust shown in me - says Pietro Gheller - For me, this is the peak of my professional career which has allowed me to acquire important skills in the direct management of global teams and to adopt an increasingly more strategic and focused approach to results. Experiences and skills which I am proud to make use of in managing the Wood Division in every area of expertise. The international macroeconomic context is not yet fully on the industry’s side, but we can continue to focus on our team strength, the value of ongoing investments and the Group's financial solidity, to gain further market shares”. Source: SCM Group

Universal Design, Home Storage Design Trends for the Elderly

- 2024-04-15

Taiwan has entered an aging society. Reports indicate that in 2022, the number of elderly people living alone reached nearly 530,000, doubling over the past decade. As we enter an aging society, our community infrastructure and housing need to be upgraded simultaneously. Architects and interior designers should consider these details when planning new developments or public facilities to meet the future needs of residents.

Kithen and Cabinet Association Union of Taiwan invited Ms. Connie Yang , the Chief Operating Officer of He Yi Life Co., Ltd., to deliver an insightful speech on "Universal Design: Home Storage for the Elderly" on April 9th. Chairman Mr.Jeff Chen is particularly grateful to Director Yang for taking the time to provide the key points in the design of home storage for the elderly. After the lecture, a test will be conducted. Those who pass the test will be awarded the "Senior Living Space Storage Specialist" certificate. He also hopes that member manufacturers will not only obtain relevant majors but also be able to It is of substantial benefit to its company’s operations

.jpg)

The key points are summarized as follows:

.jpg) Universal design, founded by American designer Dr. Ronald L. Mace in 1980, is a doctrine that emphasizes inclusivity in design, originating from Dr. Mace's personal experience as a person with disabilities. He outlined seven design principles:

Equitable use

Universal design, founded by American designer Dr. Ronald L. Mace in 1980, is a doctrine that emphasizes inclusivity in design, originating from Dr. Mace's personal experience as a person with disabilities. He outlined seven design principles:

Equitable useFlexibility in use

Simple and intuitive use

Perceptible information

Tolerance for error

Low physical effort

Size and space for approach and use

These principles are applicable to the general public and have become crucial design principles for designers. Home storage is closely related to home design. When designing a project, consideration must be given to the age, gender, and living arrangements of the users. Details such as brightness, voltage settings for electrical appliances such as electric beds, and bathroom space planning should be incorporated from the outset. Cleaning, organizing, and storage: Cleaning refers to keeping the environment clean.

Organizing means arranging items neatly.

Storage involves systematic and logical organization of items.

Most vulnerable areas in the home: Kitchen

Bedroom

Living room

Bathroom

Common accidents in the kitchen include burns, cuts, and falls. Therefore, safety in cooking and design of the sink area, countertop, and cooking area are crucial. Additionally, ergonomic cabinet door handles and easy-to-reach storage solutions are important. For the bedroom, safety considerations include planned movement pathways, fall prevention, adequate lighting, power outlets, caregiver space, visible storage, and ease of use. In the living room, safety measures, lighting, remote-controlled lighting, caregiver space, visible storage, and clear labeling of storage spaces are essential. Bathroom design should focus on wet and dry separation, use of partitions or curtains, and safety equipment like bathtub aids and slip-resistant flooring. In conclusion, when organizing storage in elderly homes, attention should be paid to cleaning, organization, accessibility, safety, simplicity in design, use of assistive tools, and regular inspections. With these basic design concepts and storage techniques, elderly home organization can be made easier and more efficient. Aging should not be feared, and with proper planning and preparation, aging in place is achievable, making nursing facilities not the only option for every elderly person. With thoughtful home design and preparations made in advance, aging in place can become a reality.

HOMAG enters into strategic partnership with Luli

- 2024-04-11

Schopfloch, April 10,2024 – In the fourth quarter of 2023,HOMAG already received a major order from China.The contact with the Chinese customer Luli Wood Industry has a term of three years and covers the delivery of a comprehensive package of machines and systems for furniture production.The total value of the order is approximately EUR 90 million. The renewed strategic cooperation between HOMAG and Luli Wood Industry was formally sealed with a traditional signing ceremony, which was attended by Zhong Duzhang, Deputy General Manager of the Luli Group, and Dr. Daniel Schmitt, CEO of the HOMAG Group, as well as other representatives of both companies. “We decided to work with HOMAG again because the company offers advantages in the field of Industry 4.0, has extensive industry experience and has been active in China for more than 40 years,” Zhong Duzhang explained during the ceremony. The value added for the major order will be created in both Germany and China. HOMAG is relying on a mixture of Chinese and German teams for installation, commissioning, and service at Luli Wood Industry. “We are very pleased to have received this order. It also shows that the Chinese market is extremely dynamic and important for us,” Dr. Daniel Schmitt emphasized. Source: HOMAG Group

SCM at DACH+HOLZ International 2024: expertise and innovation for the timber construction industry

- 2024-02-16

The stars of the SCM stand will be the OIKOS XS cnc machining centre and the new Maestro active beam&wall HMI software.

Stuttgart, 5-8 March 2024

Hall 10, stand 421

SCM returns to DACH+HOLZ International with state-of-the-art innovations and a rich programme of technical demonstrations and insights dedicated to the timber construction industry.

The result of continuous investment in research and development and the Italian Group's constant focus on the latest requirements of the green building industry will be on show in an exhibition space dedicated to high technology and the latest trends in the sector (Hall 10, Stand 421).

Prominent on the stand will be the OIKOS XS cnc machining centre, which visitors to the fair will be able to see in action in all its potential, thanks to demos dedicated to the production of specific structural elements: different types of timber frame walls, roof portions, structural beams and elements with X-fix connection.

Other demos will be dedicated to software, to experience live the advantages offered by the new Maestro active beam&wall HMI, transversal to all models of the Oikos and Area ranges of CNC machining centres for timber construction.

The Stuttgart event will also be an opportunity to take a closer look at the entire SCM range for the timber construction industry: in a cosy SCM Arena, presentations will be given on the other new additions to the wide range of cnc solutions such as OIKOS XL+ and DMC SYSTEM XL, automatic sanding-calibrating machine, as well as discovering the latest trends together with green building experts.

TECHNOLOGY HIGHLIGHTS

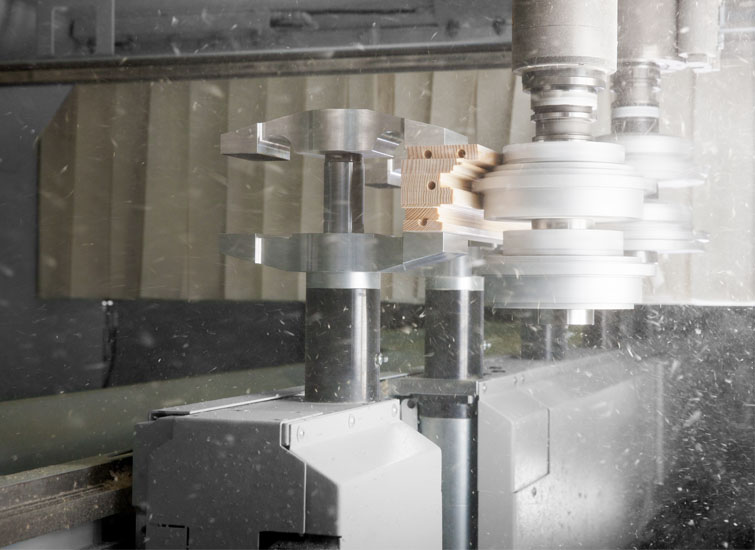

OIKOS XS: speed of execution and high configurability

OIKOS XS is the most versatile model in the Oikos range, cnc machining centre for timber construction ideal for companies looking for high speed and precision combined with a small footprint and low cost.

It is suitable for the production of straight beams, prefabricated walls, trusses, roofs and blockhouses, i.e. structural elements requiring both very fast operations such as cutting, and more complex operations such as drilling, routing, dovetails and slots for hardware, on pieces that can have a maximum length of 16 metres, a maximum width of 450 mm and a maximum thickness of 240 mm.

The speed of execution is one of the main advantages, because the work piece feed rates can increase up to 3 m/sec. Furthermore, combined movements of the operating units cut down unproductive time due to axis repositioning.

OIKOS XS enables the coverage of the work piece 6 faces. Several operating units strategically positioned within the work area, resulting in a high degree of configurability to meet every specific customer need. Another plus is the innovative 4+1 axes revolver unit with differentiated speeds for each tool which allows for a unique finish.

The machine also stands out for its machining precision, which is achieved by extremely stiff clamping system for work piece feed, horizontal and vertical pressure rollers located close to the work area, a dynamic work piece support system active during processing and a laser probe to realize precise dovetails.

OIKOS XS is the most versatile model in the Oikos range, cnc machining centre for timber construction ideal for companies looking for high speed and precision combined with a small footprint and low cost.

It is suitable for the production of straight beams, prefabricated walls, trusses, roofs and blockhouses, i.e. structural elements requiring both very fast operations such as cutting, and more complex operations such as drilling, routing, dovetails and slots for hardware, on pieces that can have a maximum length of 16 metres, a maximum width of 450 mm and a maximum thickness of 240 mm.

The speed of execution is one of the main advantages, because the work piece feed rates can increase up to 3 m/sec. Furthermore, combined movements of the operating units cut down unproductive time due to axis repositioning.

OIKOS XS enables the coverage of the work piece 6 faces. Several operating units strategically positioned within the work area, resulting in a high degree of configurability to meet every specific customer need. Another plus is the innovative 4+1 axes revolver unit with differentiated speeds for each tool which allows for a unique finish.

The machine also stands out for its machining precision, which is achieved by extremely stiff clamping system for work piece feed, horizontal and vertical pressure rollers located close to the work area, a dynamic work piece support system active during processing and a laser probe to realize precise dovetails.

New HMI Maestro active beam&wall for quick and easy all-round control

Maestro active beam&wall is the new human-machine interface software dedicated to CNC machining centres for timber construction, which offers numerous functions in a simple and fast way:

Multi-project: it allows the production of elements of the same section but which are part of different projects to be optimised on the same raw bars, in order to minimise material waste. The optimisation process is fully automatic.

3D visualisation: possibility of exploring the workpiece and taking measurements. On the 3D element, the tool paths of the machining units are traced in real-time.

Complete job management: management of routine maintenance, machine alarms, work shifts, printing of labels and creation of production reports... these are just some of the functions that the software makes available to the customer.

Advanced user management: different levels of authorisation can be enabled for each machine operator depending on their capabilities, in order to protect the machining centre from incorrect manipulation.

The new version of the HMI software is characterised by a totally renewed graphic interface aligned with that of the latest generation of software. Maestro active beam&wall is based on Maestro active, the HMI software adopted by the entire SCM Group for complete job order management.

Last but not least, the presence of the new eye-M top plus operator console compatible with all models in the Area and Oikos ranges. On the same console, upon request, the Maestro beam&wall programming software can also be installed, closely connected to the HMI software. The possibility of using Maestro beam&wall both on a PC in the office and on the operator console, i.e. directly on the machine even for the programming phase, is an important advantage for companies that reckon on flexibility of use to increase their productivity.

OTHER NEW PRODUCTS PRESENTED IN DIGITAL MODE

OIKOS XL+ for great eco-sustainable challenges

OIKOS XL+ is the new CNC machining centre for the production of columns and structural beams with a max. cross-section of 1250x610 mm. This solution has inherited all characteristics of OIKOS XL, a machining centre chosen by leading companies both in Europe and North America, amplifying all its advantages, thanks to the implementation of a second independent machining unit with a 1150 mm diameter saw blade.

New HMI Maestro active beam&wall for quick and easy all-round control

Maestro active beam&wall is the new human-machine interface software dedicated to CNC machining centres for timber construction, which offers numerous functions in a simple and fast way:

Multi-project: it allows the production of elements of the same section but which are part of different projects to be optimised on the same raw bars, in order to minimise material waste. The optimisation process is fully automatic.

3D visualisation: possibility of exploring the workpiece and taking measurements. On the 3D element, the tool paths of the machining units are traced in real-time.

Complete job management: management of routine maintenance, machine alarms, work shifts, printing of labels and creation of production reports... these are just some of the functions that the software makes available to the customer.

Advanced user management: different levels of authorisation can be enabled for each machine operator depending on their capabilities, in order to protect the machining centre from incorrect manipulation.

The new version of the HMI software is characterised by a totally renewed graphic interface aligned with that of the latest generation of software. Maestro active beam&wall is based on Maestro active, the HMI software adopted by the entire SCM Group for complete job order management.

Last but not least, the presence of the new eye-M top plus operator console compatible with all models in the Area and Oikos ranges. On the same console, upon request, the Maestro beam&wall programming software can also be installed, closely connected to the HMI software. The possibility of using Maestro beam&wall both on a PC in the office and on the operator console, i.e. directly on the machine even for the programming phase, is an important advantage for companies that reckon on flexibility of use to increase their productivity.

OTHER NEW PRODUCTS PRESENTED IN DIGITAL MODE

OIKOS XL+ for great eco-sustainable challenges

OIKOS XL+ is the new CNC machining centre for the production of columns and structural beams with a max. cross-section of 1250x610 mm. This solution has inherited all characteristics of OIKOS XL, a machining centre chosen by leading companies both in Europe and North America, amplifying all its advantages, thanks to the implementation of a second independent machining unit with a 1150 mm diameter saw blade.

In line with the increased expansion of multi-storey wooden buildings globally, OIKOS XL+ has been designed to overcome even the most complex challenges. The robust and adequately sized structure of the machine means very heavy elements of up to 4 tons can be processed, as well as very hard materials.

Flexibility is another key point, in fact any operation on any side of the work piece can be performed with no need of repositioning, thanks to the innovative 6-axis architecture of the main machining unit. Productivity and precision are other primary requirements that are the basis of this model.

The second 5-axis saw blade unit allows a blade radius of an impressive 400 mm. Furthermore, the use of a saw blade rather than a chainsaw aggregate means to work faster and achieve a better quality.

Another advantage is the ability to execute cuts from bars with a maximum thickness of 610 mm. Decisive is the machining strategy behind the OIKOS XL+, which combines the second saw blade unit with the main machining unit that has a 740 mm diameter saw blade.

In line with the increased expansion of multi-storey wooden buildings globally, OIKOS XL+ has been designed to overcome even the most complex challenges. The robust and adequately sized structure of the machine means very heavy elements of up to 4 tons can be processed, as well as very hard materials.

Flexibility is another key point, in fact any operation on any side of the work piece can be performed with no need of repositioning, thanks to the innovative 6-axis architecture of the main machining unit. Productivity and precision are other primary requirements that are the basis of this model.

The second 5-axis saw blade unit allows a blade radius of an impressive 400 mm. Furthermore, the use of a saw blade rather than a chainsaw aggregate means to work faster and achieve a better quality.

Another advantage is the ability to execute cuts from bars with a maximum thickness of 610 mm. Decisive is the machining strategy behind the OIKOS XL+, which combines the second saw blade unit with the main machining unit that has a 740 mm diameter saw blade.

DMC SYSTEM XL: built bigger to work harder

Two years after the launch of DMC SYSTEM XL, automatic sanding-calibrating machine for timber construction sector, with its firsts three modules (roller, pad and crossbelt units), the machine has been further enriched with new units that enable to process both top and bottom face of CLT panels up to 3.700 mm wide and 500 mm thick.

New features presented at Dach+Holz 2024 are: bottom roller unit, top/bottom pad unit and “piggyback” crossbelt unit, modules that can be fully combined and integrated with each other according to the customer's production requirements, by offering very high configuration versatility (a distinctive plus of DMC SYSTEM XL) and unification of components and common parts to optimize operating costs.

The solid steel structure is conceived to last long and withstand the most intense machining, by granting zero-vibration. Furthermore, the automatic sanding-calibrating machine has been developed to make the operator's maintenance work easy, fast and always safe.

Energy saving is a key issue: the machine has been specifically engineered with an optimized design and technological solution for minimum compressed air consumption.

Even this solution, as well as all SCM sanding technological offer, is aimed at improving the surface finishing and increase the value of the finished product. Reflecting the latest market trends in having visible CLT walls and a product that is as natural as possible (without resorting to additional surface treatments).

Source: SCM Group

DMC SYSTEM XL: built bigger to work harder

Two years after the launch of DMC SYSTEM XL, automatic sanding-calibrating machine for timber construction sector, with its firsts three modules (roller, pad and crossbelt units), the machine has been further enriched with new units that enable to process both top and bottom face of CLT panels up to 3.700 mm wide and 500 mm thick.

New features presented at Dach+Holz 2024 are: bottom roller unit, top/bottom pad unit and “piggyback” crossbelt unit, modules that can be fully combined and integrated with each other according to the customer's production requirements, by offering very high configuration versatility (a distinctive plus of DMC SYSTEM XL) and unification of components and common parts to optimize operating costs.

The solid steel structure is conceived to last long and withstand the most intense machining, by granting zero-vibration. Furthermore, the automatic sanding-calibrating machine has been developed to make the operator's maintenance work easy, fast and always safe.

Energy saving is a key issue: the machine has been specifically engineered with an optimized design and technological solution for minimum compressed air consumption.

Even this solution, as well as all SCM sanding technological offer, is aimed at improving the surface finishing and increase the value of the finished product. Reflecting the latest market trends in having visible CLT walls and a product that is as natural as possible (without resorting to additional surface treatments).

Source: SCM Group

HOMAG Technology Days 2024

- 2024-02-15

New solutions, new possibilities… in our showrooms throughout Germany

At HOMAG Technology Days, visitors can discover exclusive solutions in the areas of panel dividing, CNC, edge processing, digital solutions, automation and more, first hand at HOMAG locations throughout Germany. In addition to machines, digital products and production methods, the main focus of these special events is interaction and dialog with YOU! Together, we will immerse ourselves in the latest woodworking technologies - with the right focus on your unique needs.

Technology Days at a glance:

- 12.-14. March – Focus: Sawing, Cutting and Panel Dividing in Holzbronn

- 10.-12. April – Focus: CNC and Edge Processing in Herzebrock

- 16.-17. April – Focus: Building Component Manufacturing in Schopfloch

- 14.-15. Mai – Focus: Edge Processing and Automation in Schopfloch

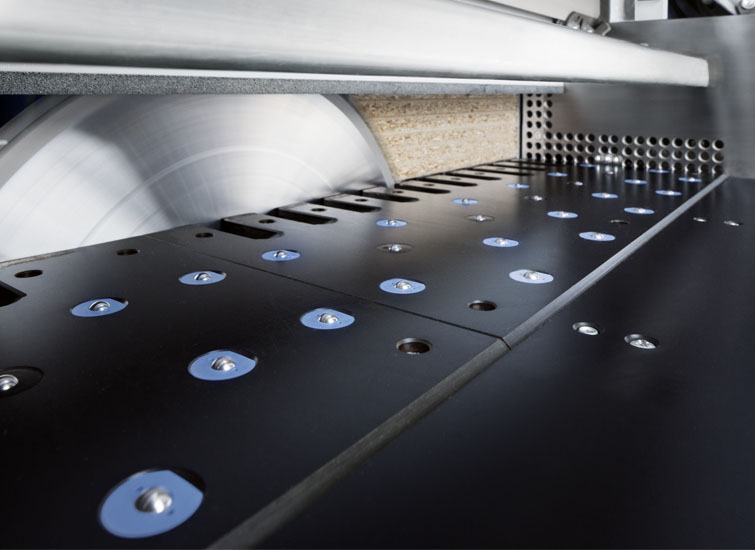

Focus: Sawing, Cutting and Panel Dividing

12.-14. March 2024, Holzbronn

-

In Holzbronn, visitors will experience state-of-the-art technologies for perfect panel dividing, from material handling to advanced production. The spectrum ranges from precise cuts to intelligent material utilization.

Our highlights:

- Perfect entry-level solutions: The SAWTEQ S-200 and the updated SAWTEQ S-300 flexTec robotic saw, fed by STORETEQ F-100 single-axis feeder

- NEW: Flexible nesting with the CENTATEQ N-210, combined with the STORETEQ P-300 storage system (with new woodStore features), and the new generation of SAWTEQ S-300 as a “storage-saw-nesting” cell concept

-

The extended opening hours are another special feature. They offer all visitors the ideal opportunity to talk shop and enjoy a relaxed exchange between experts, during the workday or at the end the day after their work is done.

Opening hours:

- Tuesday, 12.03.2024: 11:00 – 20:00

- Wednesday, 13.03.2024: 11:00 – 20:00

- Thursday, 14.03.2024: 09:00 – 17:00

-

Focus: CNC and Edge Processing

-

10.-12. April 2024, Herzebrock

-

.jpg)

-

Visitors to Herzebrock will discover innovative CNC and edge processing solutions for the workshop. HOMAG will show visitors new perspectives and various options for optimizing work processes, from digital workflows and smart machine integration concepts to automated production solutions. And of course, individual machines for your individual needs.

Our highlights:

- NEW: EDGETEQ S-200 with new, top-mounted gluing unit for PUR or EVA

- NEW: EDGETEQ S-380 with the new, material friendly LOOPTEQ O-400 return conveyor

- DRILLTEQ V-310 with automatic material return and new integrated turning function

- Experience over 1,600 m² of state-of-the-art technology in one compact location – complemented by suitable automation solutions and smart digital helpers

-

Focus: Building Component Manufacturing (Windows, Stairs, Doors)

16.-17. April 2024, Schopfloch

-

From idea to production: During the Technology Days with a focus on component production in Schopfloch, visitors will discover technologies that facilitate and optimize the production of high-quality windows, stairs and doors.

Our Highlights:

- Celebrate 25 years of HOMAG window production technology!

- See the CENTATEQ S-800/S-900 for automated window production, bar processing and block frame production – from entry-level to customized system concepts

- Whether you’re producing staircases, furniture, windows, doors or interior fittings – with

- the CNC processing centers of our CENTATEQ series, you have all the tools you need

- Informative specialist presentations: From experts for experts

- Personal exchange with other industry experts

-

Focus: Edge Processing and Automation

14.-15. May 2024, Schopfloch

-

Perfect edges for perfect results. At the Technology Days with a focus on edge processing and automation in Schopfloch, HOMAG is focusing on outstanding edge processing with the right automation solutions - from the entry-level versions to fully automatic part circulation.

Our Highlights:

- NEW: EDGETEQ S-200 with new, top-mounted gluing unit for PUR or EVA

- NEW: EDGETEQ S-500 with the new, material friendly LOOPTEQ O-400 return conveyor

- Edge cells from small to large: From the EDGETEQ S-380 with LOOPTEQ O-300 return conveyor, to the EDGETEQ S-500 with LOOPTEQ O-600, up to the EDGETEQ S-800 with LOOPTEQ C-500 edge circulation unit

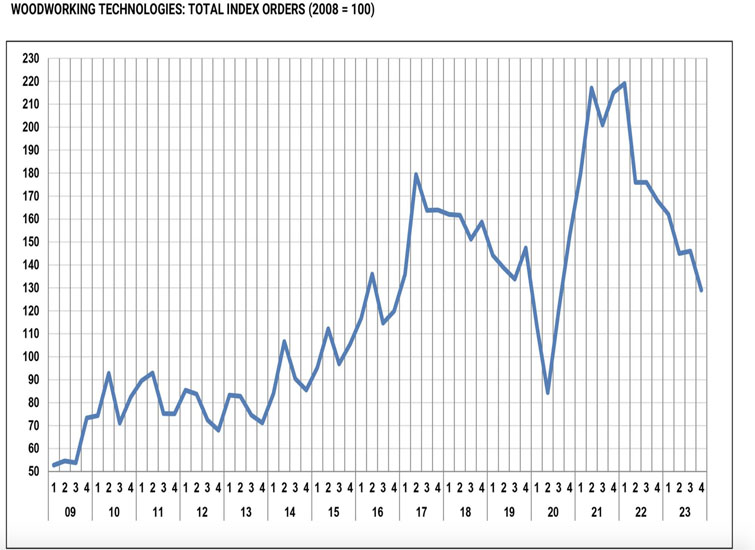

WOODWORKING TECHNOLOGY: FOURTH QUARTER STILL DECLINING

- 2024-02-14

After the booming growth of recent years, another negative quarter is expected for the processing industry of wood and wood-based materials. This trend is emerging from the traditional quarterly survey carried out by the Studies Office of Acimall, the association of Italian woodworking and furniture technology manufacturers, which continues to show a falling trend for orders, in line with the previous quarters. The October-December 2023 figures show an overall reduction of orders by 23.6 percent compared to the same period of 2022, resulting from the combination of incoming orders from abroad (minus 6.3 percent) and a sharp decline in domestic demand (minus 48.1 percent), largely due to a wait-and-see attitude encouraged by the expected implementation of the new “Industria 5.0” measures. So, the back-to-normal trend after the exceptional results of 2020-2022 has combined with the wait for the new decree, whose details are being delayed, inevitably causing a negative impact on investment decisions for instrumental goods. However, the wood and furniture technology industry can still rely on a significant order backlog of 4.5 months, having saved for a rainy day in the past years when demand was high. Prices are rallying, up by 1.9 percent since January 2023. According to the quality survey, 55 percent of the interviewed companies expect substantial stability in production, while 25 percent predict an increase and 20 percent further reduction. 10 percent of interviewed companies expect increasing employment, while 70 percent indicate substantial stability and 20 percent fear a reduction. Available stocks are stable according to 50 percent of the interviewees, increasing for 20 percent and decreasing for 30 percent. Let’s take a look at the results of the forecast survey: on the domestic market, the figures processed by the Studies Office of Acimall reveal that 50 percent of the sample expect stability, 15 percent increasing orders and 35 percent a reduction. Expectations are more balance for the foreign markets: 40 percent said the trend will remain stable, while things will get worse according to 35 percent. The remaining 25 percent expect an increase in orders. “We can only repeat what we have been saying for months”, said Acimall Director Dario Corbetta. “In recent times, our industry has benefited from a very positive situation that could not last forever, and now we have to face a return to pre-Covid levels”. This situation must not scare Italian companies, as they are perfectly fit to face any situation, as the history of our industry shows. For sure, the definition of details of the “Industry 5.0” decree and its tangible consequences might have a strong impact on the trends emerging from our data, and this is the direction where the entire community of mechanical engineering is heading”. Source:ACIMALL